Fiber Optic Gyro Winding Machine-REPOSAL? Winding Machine Official Website

Compared with mechanical gyroscopes, fiber optic gyroscopes have no moving parts, impact resistance, high sensitivity, and long life. Therefore, fiber optic gyroscopes are widely used in high-precision and high-speed positioning scenarios and will gradually replace electromechanical gyroscopes.

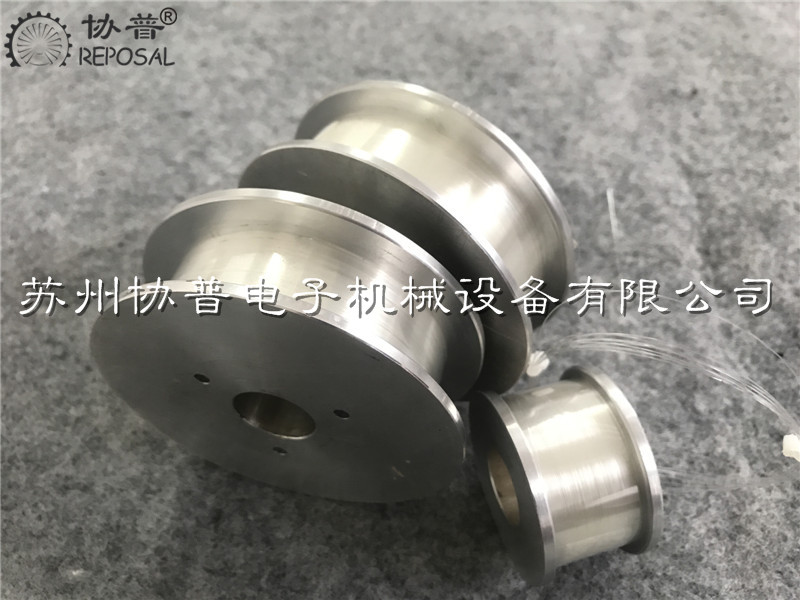

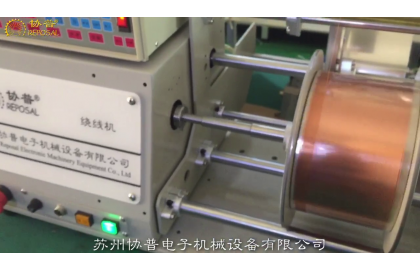

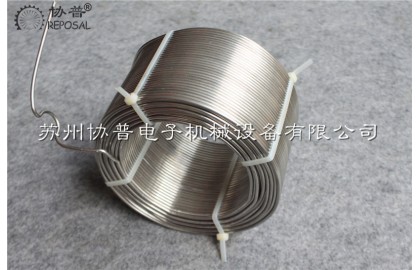

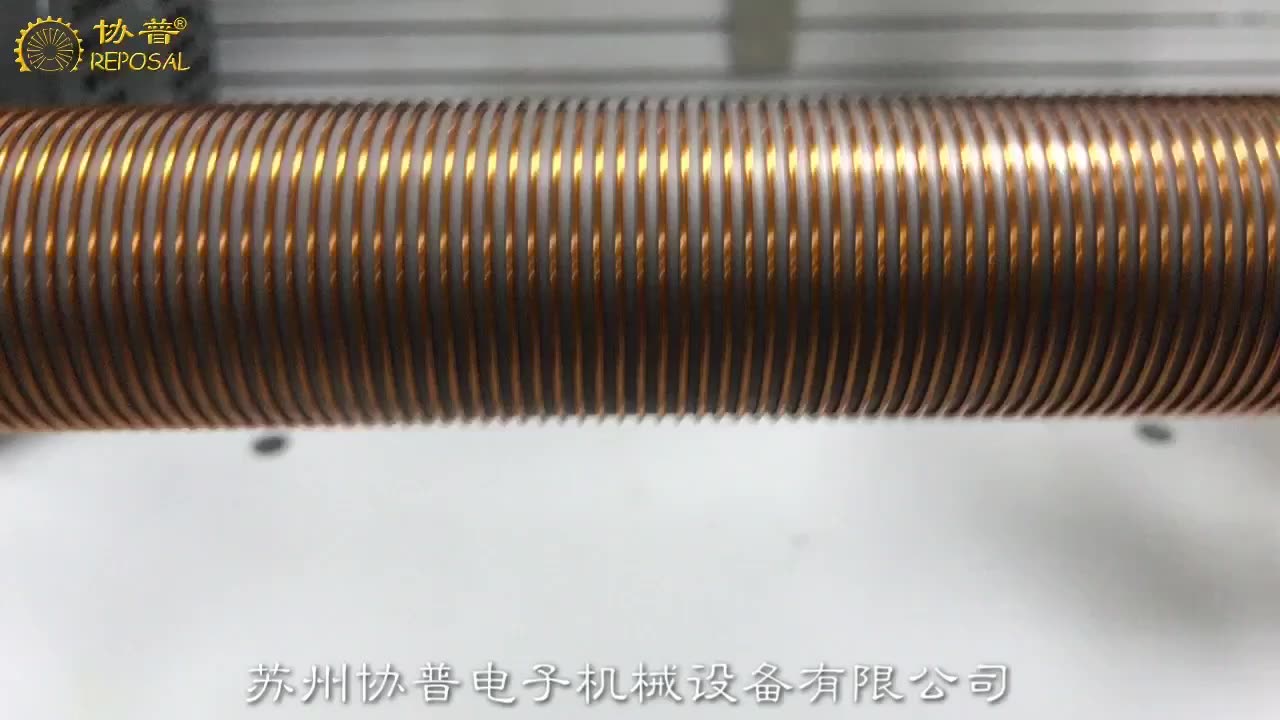

The basic components of the fiber optic gyroscope are the optical path and the circuit, and the fiber is the core component of the gyroscope. The fiber winding machine for preparing high-precision fiber coils has also become the key point of the gyroscope.

However, due to the blockade of its related technologies, the fiber optic gyro winding machine has always been a key technology insurmountable. REPOSAL? Electronic Machinery Co., Ltd. actively develops fiber optic gyro winding machines in response to market demand.

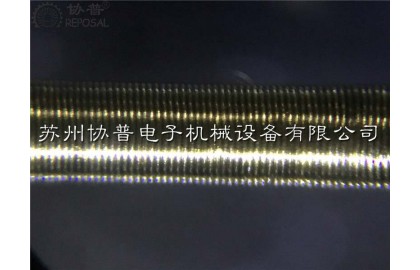

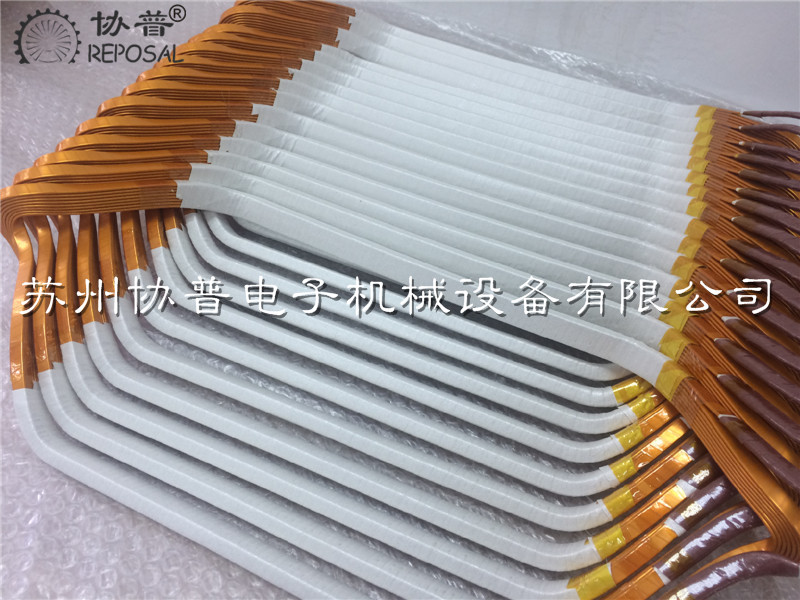

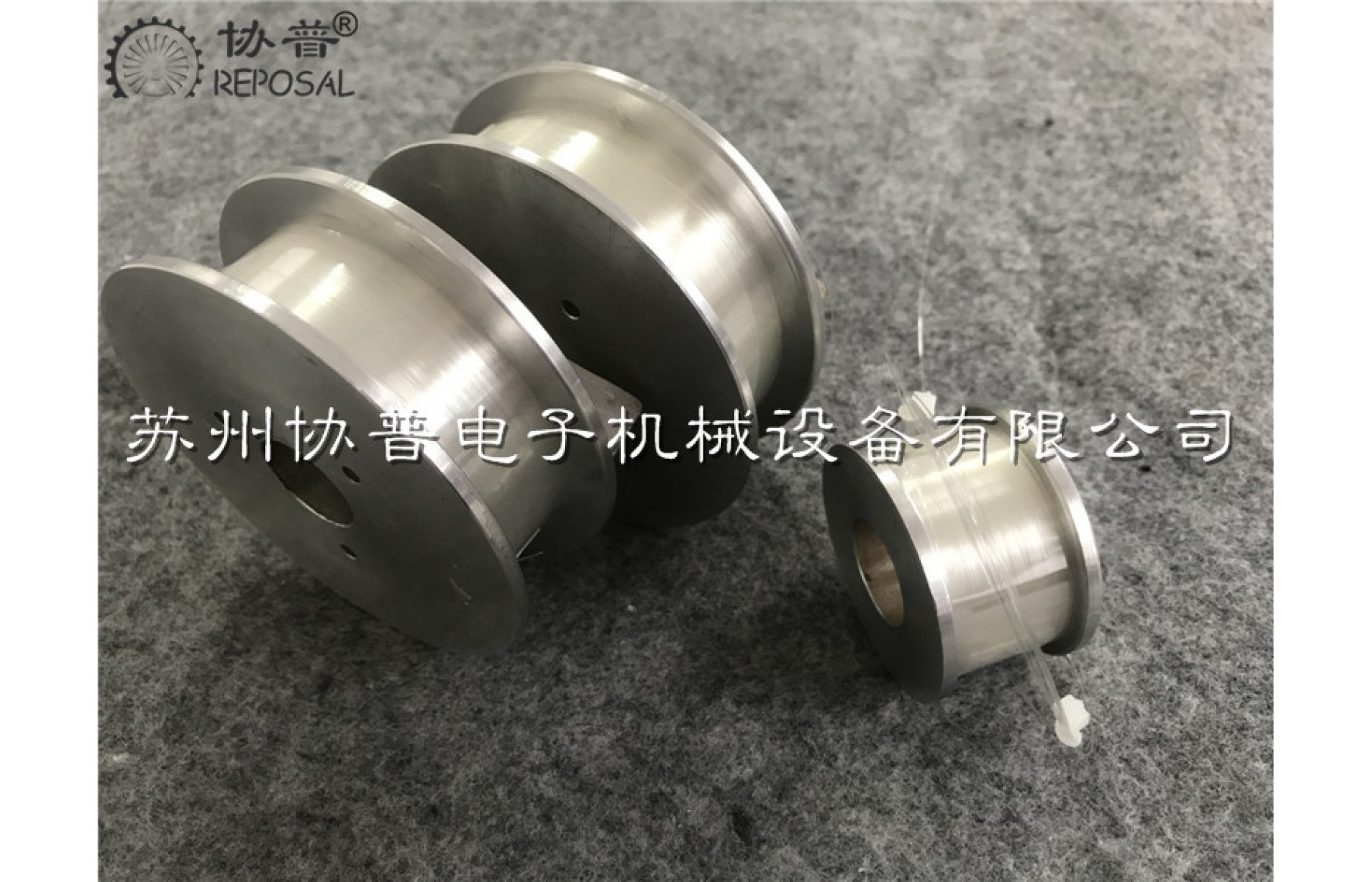

Through continuous research and improvement, we automate the winding process of the fiber optic gyroscope, and compare and analyze the winding methods of various fiber coils. We have obtained that the tension control and the accuracy of the winding during the fiber winding process affect the structure of the wound fiber coil. The key factor.

By optimizing the aforementioned tension control factors and winding accuracy algorithm, the effective and stable control of reasonable tension, the effective and reliable high-precision winding control, the memory of all process parameters, and the convenience of control, a new generation of optical fiber winding machine was developed and put into production .

With the practical application of research and development results, we will continue to improve and produce high-reliability and high-efficiency fiber optic gyro winding machines.

Related Post

Design and verification of winding machine for precision voltage transformer

In power transmission and power supply systems such as power plants and substations, voltage transformers are an indispensable electrical appliance. The voltage transformer for measurement specifies the accuracy level of the voltage transformer according to the error generated when the voltage is changed. Voltage transformers of level 0. 2 and above are generally called precision voltage transformers, which are mainly used in the laboratory to expand the measurement limit with the standard meter for precise measurement of voltage, power and electrical energy; or as a standard to check low standards, Low-accuracy voltage transformer; it can also be used with standard meters to test the corresponding meters.

With the rapid development of science and technology and electronic application technology, the requirements for technical indicators such as the rated primary voltage and accuracy of voltage transformers are getting higher and higher, and the demand for various types of voltage transformers is increasing. In the past, voltage transformers were mostly manually wound with annular iron cores and thick enameled wires. The products were large and heavy. In the daily winding, processing and production process, the degree of mechanization was not high, the labor intensity of workers was high, and the production efficiency was low. It is necessary to improve the voltage transformer design process and develop a new type of mechanical equipment for winding the voltage transformer.

REPOSAL? successfully developed an ultra-precision flow tube metering heating wire winding machine

On August 6, the first ultra-precision flow tube metering heating wire winding machine independently developed by Suzhou REPOSAL? Electronic Mechanical Equipment Co., Ltd. successfully completed the test, and the performance of each index reached the level of the industry in advanced foreign countries.

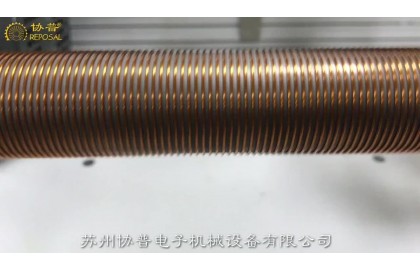

At present, the ultra-precision flow tube, a metal tube with a diameter of 0.4mm, a wall thickness of 0.1mm, an inner diameter of 0.2mm, and a special metal wire of 0.03mm are wound. There are single-layer winding, double-layer winding, and double-layer butt-joining winding. Flow tube is required There is no deformation at both ends and the metal wires are arranged neatly. This process technology has been monopolized by foreign companies for a long time, and the price is high, which severely restricts the research and achievement of ultra-precision flow meters in China.

Ultra-precision flow tube metering heating wire winding machine is an important symbol of independent innovation ability. The research of this equipment has broken through many key technologies of precision winding technology and optimized the process and mechanical structure. In the next step, Suzhou REPOSAL Electronic Machinery Equipment Co., Ltd. will further optimize the design and production process, reduce the cost of the whole machine, make it better to market, and accelerate the application and industrialization of localized precision winding machines.

Classification and difference of transformer winding machine

Classification and differences of common transformer winding machines

Choosing the right winding machine is the key to the production of coils. There are many types of winding machines as the basic equipment. This article mainly takes transformer winding machines as an example, and talks about its classification and differences, generally according to the voltage level or capacity of the transformer. Division, the common ones are ordinary CNC winding machines, automatic winding machines, foil winding machines, and vertical winding machines, etc.

Enameled wire production process

Enameled wire technological process: pay-off→anneal→paint→baking→cooling→take-up

1. Pay-off On a normally operating enameled machine, most of the operator's energy and physical strength are consumed in the pay-off part. The replacement of the pay-off reel makes the operator pay a lot of labor, and the joints are prone to quality problems when changing the line. An operating failure has occurred. An effective method is to pay off with large capacity.

The key to pay off is to control the tension. When the tension is large, it will not only draw the conductor thin, make the surface of the wire lose its brightness, but also affect many properties of the enameled wire. From the appearance point of view, the enameled wire that is drawn thinner has poor gloss; from the performance point of view, the elongation, resilience, flexibility, and thermal shock of the enameled wire are all affected. If the pay-off tension is too small, the line will easily jump and cause the line to be merged and the line to touch the furnace mouth. When paying off, the most fear is that the half-turn tension is high and the half-turn tension is small. This will not only cause the wires to loosen, break, and be thinned section by section, but also cause large jumps of the wires in the oven, resulting in failures of merging and touching the wires. Pay-off tension should be even and appropriate.

Installing a booster wheel in front of the annealing furnace is very helpful for tension control. The maximum non-extension tension of soft copper wire at room temperature is about 15kg/mm2, the maximum non-extension tension at 400℃ is about 7kg/mm2; the maximum non-extension tension at 460℃ is 4kg/mm2; the maximum non-extension tension at 500℃ The extension tension is 2kg/mm2. In the normal enameled wire coating process, the tension of the enameled wire is significantly less than the non-extension tension, which is required to be controlled at about 50%, and the pay-off tension should be controlled at about 20% of the non-extension tension.

Process requirements of traction motor winding machine

Traction motors are mainly used for railway mainline electric locomotives, industrial and mining electric locomotives, electric drive diesel locomotives and various electric vehicles (such as battery cars, urban trams, subway electric vehicles).

The constraints of the coil during the winding process of the winding machine mainly come from two aspects: design requirements and craftsmanship. The specific manifestations are:

The structural design of coils and windings must not only meet the requirements of electrical performance and temperature rise limit, but also the applicability of existing winding machines, the economical and reasonable use of electromagnetic wires and insulating materials, simple structure and convenient manufacturing, that is, it should have Good manufacturability. In order to achieve better manufacturability and reliability, there are some control points that must be considered in the early stage. For this type of problem, REPOSAL?winding machine shares some content with you.

Special miniature permanent magnet trip coil winding machine

As shown in the figure, this miniature permanent magnet trip coil is widely used by ABB, EATON Muller compact circuit breaker, and has a compact structure. On a tiny metal structure bracket, a suction coil is wound that is closed to the metal structure. It seems simple, but its design technology is very strong. Therefore, it has been the industry enterprises in this kind of products to achieve the domestic industry barriers.

With the attitude of professional focus and the trust of advanced customers in the circuit breaker industry in Mongolia, REPOSAL? winding machine has gone all out to successfully reverse crack this technological process and help customers of REPOSAL? winding machine to make this product domestically smoothly.

Introduction of winding method of electric heating tube

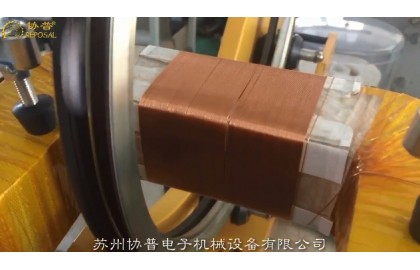

This type of winding machine of Xiepu has a stroke of 1.5 meters, adopts pneumatic quick assembly and quick disassembly, convenient operation, mature and stable structure, easy maintenance, easy operation of the system, complete functions, and strong expandability.

At present, according to customer requirements, a heating coil with a stroke of up to 1.5 meters is wound on this machine. Because the equipment is structured in place, the winding has a satisfactory effect. The customer currently plans to add mica tape winding function on this basis.

Debugging method and video of winding machine

Debugging method and video of winding machine

1. Preparation work before turning on the winding machine.

As a kind of precision equipment, in order to keep the winding machine with good working accuracy for a long time, at the same time, the winding machine is a equipment with rotation as the main movement feature. In order to ensure the safety of the process, we need to carefully check the winding machine before the machine. Whether there is debris on the workbench, whether the screws on the winding machine are loose, whether the power switch is properly connected, whether the specification of the enameled wire meets the requirements, confirm that there are no problems with the above problems before starting the machine.

2. Parameter setting of precision winding machine

Press the reset button on the winding machine controller, or press the reset button on the front of the winding machine, the winding machine will automatically reset, at this time, if you need to set the winding machine parameters according to the production schedule. Then press the "step sequence setting" "input" button on the controller of the winding machine in turn, and then press the input key, the cursor will jump backwards in turn at the prompt light on the screen, "starting point", "width" ", "wire diameter", "number of laps", "start winding slow withdrawal", "stop slow", "high speed", "low speed", "wire direction", "winding direction" and other parameters, and finally press "confirm" "Button to confirm, and press the "reset" button to save the data and reset automatically, the parameter setting is completed.

After entering the setting interface according to the step-by-step setting input, pay attention, press the input again to scroll back, and press the-number to scroll forward. When you turn to each parameter, you can enter the corresponding number according to the actual process requirements. For this parameter, you can modify the parameter by typing in the number, or you can adjust the position in real time through the right or right key at the bottom right of the winding machine controller. At the same time, the number in the parameter box will change accordingly in real time.

Analysis and Solution of Common Defects in Coil Winding Machine

Analysis and Solution of Common Defects in Coil Winding Machine

one. Bad salt bath:

1. Poor enameled wire: Take out part of the enameled wire from the wire barrel (stretch a few times) and put it in salt water to judge.

2. Poor tension of the winding machine (too large): The rotor wire package placed in salt water bubbles irregularly, and the value rises slowly. (Too small): The wire is easy to hang on the steel sheet during the winding process and the wire package is large and loose.

Solution: The enameled wire passing through the tension system of the winding machine must be checked with a spring balance on the tension meter before winding.

3. Wool felting carbon. Damage to the winding wheel of each winding machine. Damage to the small bearing of each winding: The rotor wire package placed in salt water bubbling irregularly, and the value rises faster.

Solution: Replace the damaged wool felt, thread roller, and small bearing

4. Damage to the winding mold of the winding machine (wire mold): The rotor wire package placed in salt water bubbles regularly, and the bubble position is in the upper, lower or middle of the iron core (each slot is in the same position). The value rises quickly.

(Hook wire set): The rotor wire put in the salt water bubbling on the neck (the damage part should be visible).

Solution: Check the mold. Determine the position. Grind and polish.

5. Poor debugging of the winding machine caused the indexing change during the winding process (and even scratches on the bottom of the enameled wire): the winding mold of the winding machine was not adjusted well at the center of the hook sleeve, and the balance of the winding mold was not adjusted properly. Hook thread set

Instructions for use of side-sliding transformer winding machine

Instructions for use of side-sliding transformer winding machine

Clamp Ammeter Coil Winding Machine|Clamp Meter Coil Winding Machine|Semicircle Transformer Winding Machine

Clamp Ammeter Coil Winding Machine|Clamp Meter Coil Winding Machine|Semicircle Transformer Winding Machine

The semi-circular coil winding machine developed by Suzhou Xiepu Electronic Mechanical Equipment Co., Ltd. is suitable for the winding of semi-circular skeleton, iron core and magnetic core coil. Its running operation, high speed, safety cover is convenient and practical. Fast and repeatable positioning accuracy. Applicable products are: semi-circular transformer coil, semi-circular heating wire coil, clamp meter coil, etc.

Gear type ring coil wrapping tape machine

Gear type ring coil wrapping tape machine

Compared with the belt-type loop coil tape belt machine, the gear-type loop coil tape belt machine has a larger processing range and more storage capacity. Our company's gear-type loop coil belt tape machine can be coated with polyester film and polymer Imide, cloth tape, glass fiber tape, etc.

We now open the clamping seat of the gear-type ring coil tape belt machine, the storage ring opens, and then put the product on, the storage ring buckles, the clamping seat merges, and then pay attention to the insulating tape must pass through the middle of the scissors, etc. Cut it off with scissors at once, and then go in from any bearing above the storage ring from the outside to fix the tape head behind the storage ring. The first few laps are slow because they are in storage. Ok, the product is finished, now we take it off, and then close the storage ring, the clamping seat is restored.