Insulation tape winding machine

Insulation tape winding machine

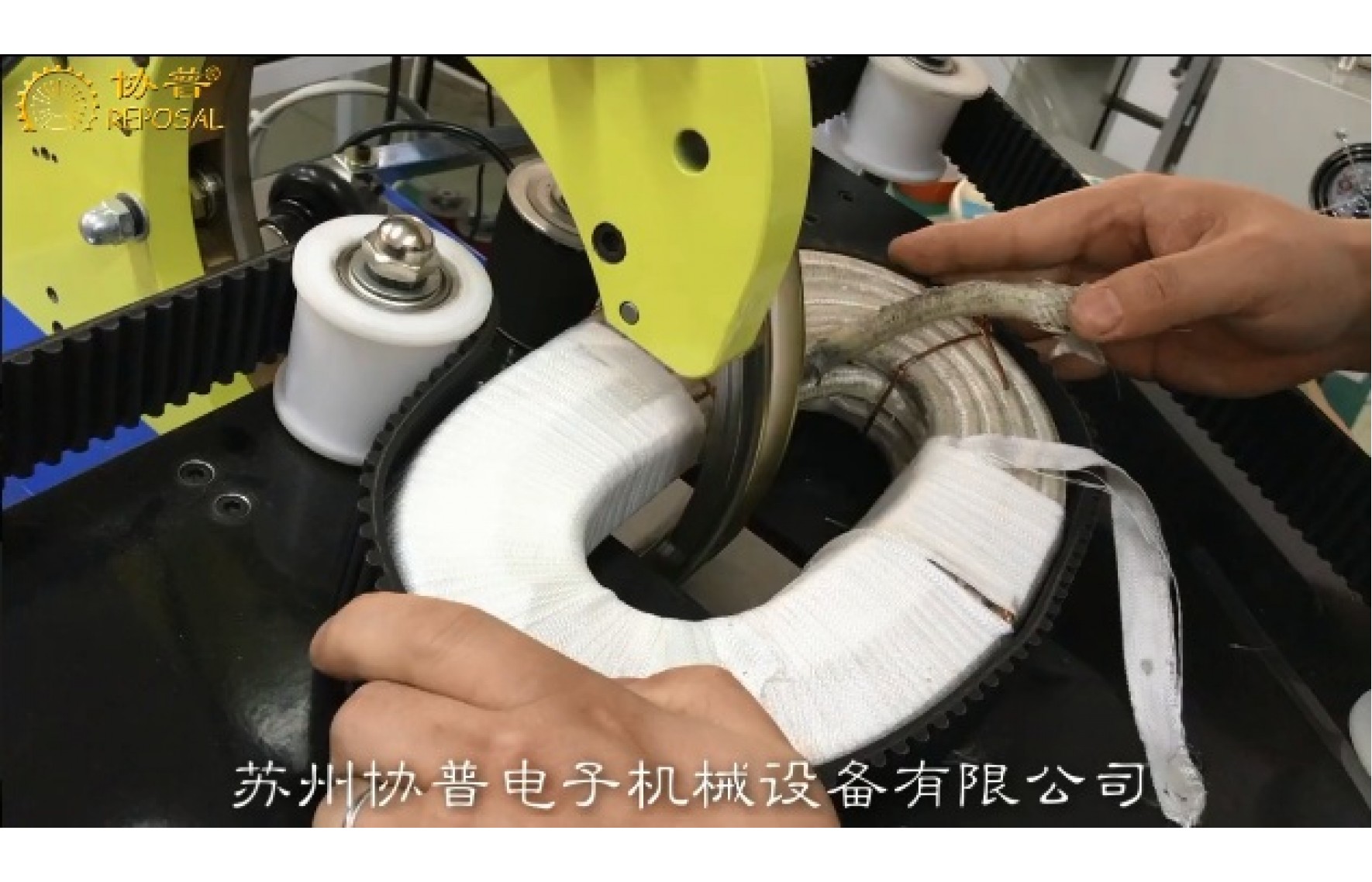

The coil in the video is used for railway braking, and the insulation material of the package is glass fiber.

The product has a spindle shape with slightly pointed ends, so it is difficult to achieve with a machine.

REPOSAL winding machine meets customer requirements by optimizing the cross-sectional shape of the winding wheel and cooperating with real-time manual intervention control.

Related Post

REPOSAL? winding machine has successfully provided competitive solutions to the electron microscopy winding process

The main components of scanning electron microscope are electron optics system, signal collection and processing system, vacuum system, image processing display and recording system, power system and computer control system. The core part is the electron optical system, which is mainly composed of electron gun, electromagnetic condenser, diaphragm, scanning system, astigator, objective lens and various centering coils.

Reposal? winding machine As a professional supplier of precision winding solutions, we focus on the electromagnetic condenser, objective and astigmatic, because the main components are enamoured wire windings, and the precision and consistency of the windings are highly related to the image quality of the scanning electron microscope.

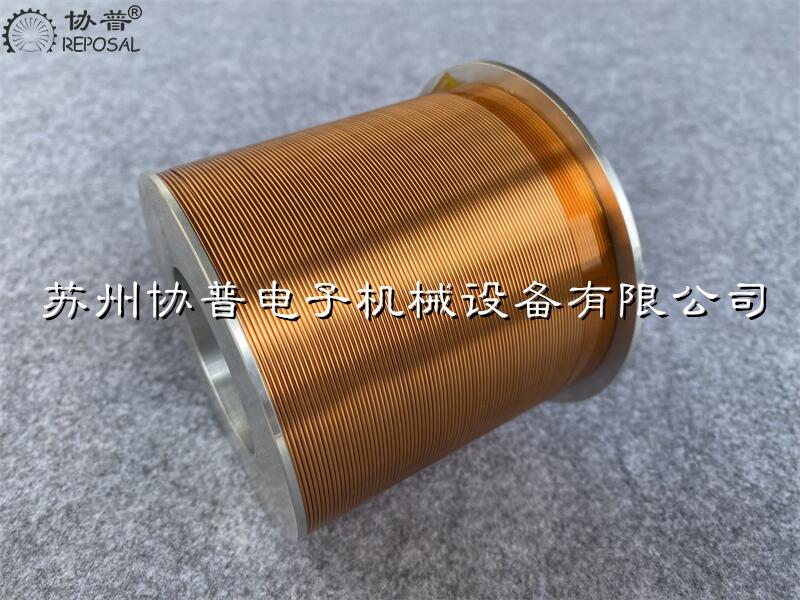

Electromagnetic lens coil.

The electromagnetic lens is mainly used to restrain the electron beam and it can be regarded as a convex lens in optics. Because the electron beam in a rotating symmetric magnetic field will be subjected to the Lorentz force, resulting in a focusing effect. Therefore, the quality of the enamelled wire winding coil that can generate this rotationally symmetric rather than uniform magnetic field and make the electron beam focus imaging is very important.

The enamelled wire winding coil in the magnetic lens, when the current passes through the coil, the pole shoe is magnetized, and a magnetic field is established in the heart cavity, producing a focusing effect on the electron beam. There are two kinds of enamelled wire winding in the magnetic lens, namely, the enamelled wire winding of the condenser and the enamelled wire winding of the objective lens. The lens near the electron gun is the enamelled wire winding of the condenser, while the one near the sample is the enamelled wire winding of the objective lens. General condenser is the high excitation lens enamelled wire winding, high excitation lens enamelled wire winding has many turns, a cylindrical multi-layer arrangement, requires good rotation symmetry

REPOSAL? Winding machine Optimum design of CNC winding machine for large power transformer

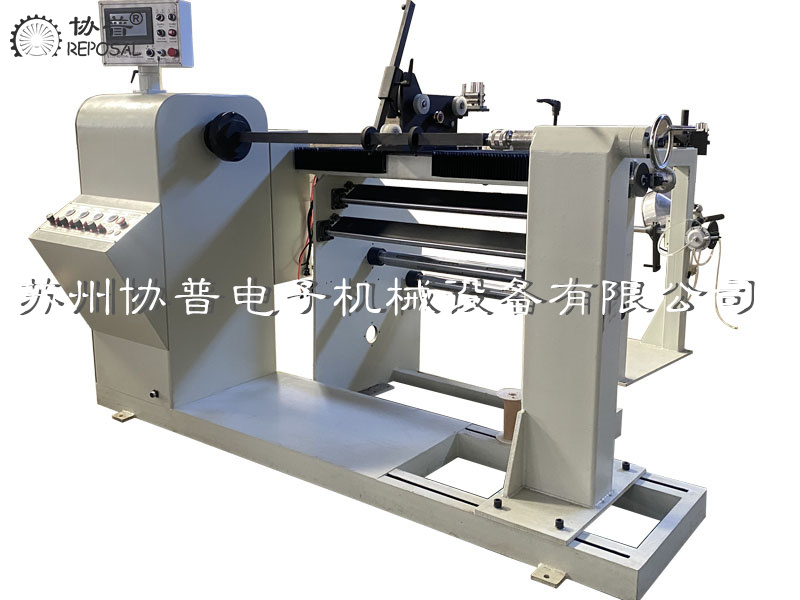

In the manufacture of power transformers, winding the transformer coil is a super important step, you think, the transformer coil is wound more firmly and neatly, the strength of the transformer and the ability to protect against short circuits can be greatly improved. However, most of the current transformer winding machines have to rely on manual extra sorting of the coil, the entire equipment is low in automation, and the production efficiency is not high, so the development of an excellent large transformer winding machine is a crucial thing for our company.

We have studied the main shaft technology of transformer winding machine, the relationship between compaction force and winding quality, and the control of compaction force. According to the principle and process flow of transformer winding, we put forward a whole design scheme of large transformer winding machine, including mechanical structure and electrical control. Mechanically, we simplify the complex structure of traditional transformer winders. In terms of electrical control, we ensure the stability of the motor when it starts and stops, and ensure that the winding coil is evenly tightened during the winding process. For the core parts of the transformer winding machine, spindle system and pressing device, we have calculated and selected the types and parameters. With the compaction device, we are able to provide real-time axial and radial compaction forces during the winding process of the transformer winding, which is very effective for improving the tightness of the winding.

The static analysis of the radial compaction device of the winding machine is also carried out by using finite element method, and the structure optimization is carried out according to the analysis results. We find that as the number of layers and turns of the winding increases, the required axial and radial compression forces change accordingly. By analyzing the experimental data, we find that there is a maximum value and a minimum value in the range of quality requirements, and it is the most reasonable choice to make the compression force approximately proportional to the number of layers and the number of turns.

The large transformer winding machine developed by our company has been preliminatively debugged and put into the market. After testing, the performance parameters of this transformer winding machine are in line with the design requirements, and the operation is stable and efficient. It can be wound to make a tight and regular transformer winding coil, and has been fully recognized by the market.

As a power grid equipment, power transformer converts voltage through the electromagnetic induction between the winding coils of the transformer. With the continuous development of the market, higher requirements are put forward for the manufacturing level of transformers, and the market needs more energy-saving and efficient transformers. Therefore, the optimization of the transformer manufacturing process is particularly critical. Quality and performance depend on the process equipment. The technical level of the transformer winding machine directly reflects the manufacturing level of the transformer. Therefore, accelerating the development of transformer winding machine is an important guarantee to improve the performance of transformer.

The winding coil of the transformer is the core component of the transformer and constitutes the electromagnetic induction part of the transformer. It generally includes high voltage winding and low voltage winding, respectively connected to the high voltage grid and low voltage grid. The winding of large power transformers usually adopts concentric winding, that is, the high and low voltage transformer winding coils are centrally set on the core column. The manufacture of transformer winding is the core process of transformer, and its quality plays a crucial role in the performance of transformer, affecting the appearance of transformer size, weight, mechanical properties, insulation and heat resistance and other important indicators.

In the past, the production of transformer winding coils relied on manual, and workers had to wind insulated wires manually to the winding die frame in accordance with the process requirements. Turns calculation also have to rely on manual, this old-fashioned method is inefficient, and because the worker's skills are not strong enough, the quality of the winding coil is poor, the number of turns may be miscalculated or missed, and ultimately lead to the finished winding coil performance can not be guaranteed. Later appeared semi-automatic transformer winding machine, which is driven by the motor to rotate the spindle to wind the transformer winding coil, although it improves the production efficiency, but the wiring work still has to rely on manual, only suitable for flat winding transformer winding coil winding, and winding head winding, welding and other operations must still be completed manually, so the product quality is not stable.

Later, with the emergence of TTL logic gate circuits, in the mid-1970s, with the development of CMOS technology, various types of equipment program control a large number of applications of digital integrated circuits, Western countries and Japan and other industrial powers have emerged CNC winding mechanism manufacturing industry. These CNC transformer winding machines represent the advanced level of winding mechanism manufacturing technology, especially the winding equipment produced in Japan, Italy, the United States and Germany is the leading technology.

Now the transformer winding machine as the core parts of the transformer production equipment, the market demand is very large, and the transformer manufacturing enterprises at home and abroad attach great importance to the development and application of advanced technology of transformer winding machine. Domestic transformer winding machine production enterprises are small, insufficient technical reserves, limited research and development funds, so there is still a big gap compared with foreign advanced products, the market share is low, unable to compete with foreign countries. To solve the key technical problems of transformer winding machine is the key to improve the quality of domestic winding equipment and enhance the market competitiveness. In order to meet the demand of transformer manufacturers for high quality and low price winding equipment, especially large transformer winding machine, on the basis of learning from foreign advanced experience, combined with domestic research results, the development of large transformer winding machine has important significance and practical value.

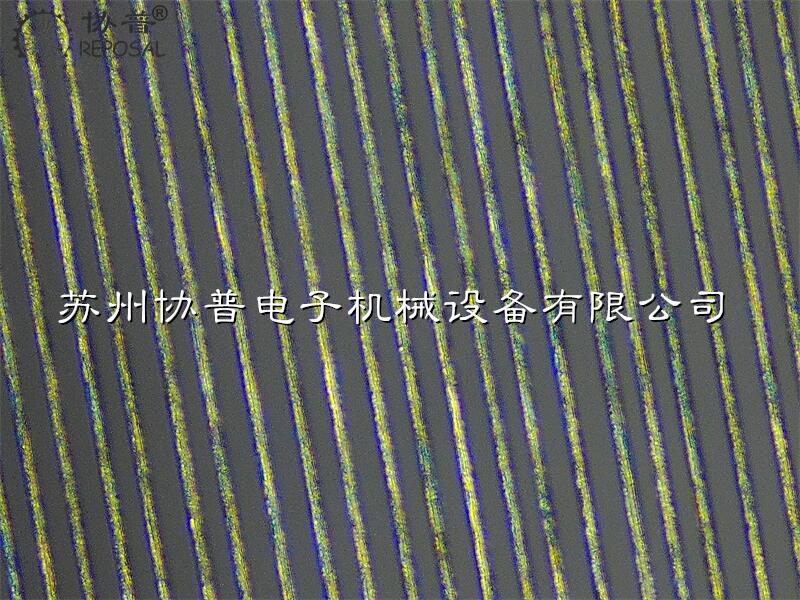

REPOSAL? winding Machine successfully overcomes the polarization grid precision winding technology

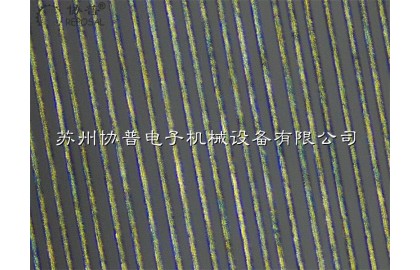

Since these polarized wire grids, which are wound by precision winding machines, have no underlying substrate, they have the advantage that they are not affected by substrate related dispersion and absorption, and there is no beam deviation during transmission. This provides a thin, compact and versatile polarization element with a high degree of polarization over a wide transmission range.

At present, because there is no professional winding machine, most of the polarization grid used in our country is imported polarization grid, and the price is expensive; However, the domestic processing method of wire grid mainly uses manual winding, which has low precision and long production cycle. At the same time, the winding machine at home and abroad is mainly used in electronic components, sensors, etc., the control variable is relatively single, and the main control mode is tight layout, even the high precision winding machine, there are few equal spacing layout for the polarization line grid, so the accuracy can not meet its needs. Therefore, it is very important for the coiler to overcome the polarization grid precision winding technology.

REPOSAL?winding machine's advantages in crossover winding machines

REPOSAL has invested a lot of R&D efforts in the field of crossover coil winding machines and has achieved a series of remarkable results.

In terms of winding accuracy, through in-depth research and optimization of the wiring mechanism and control system, REPOSAL's divider coil winding machine can control the winding accuracy within a very small error range. For example, for the wire with a thin wire diameter, the winding machine can accurately wind according to the set number of turns and arrangement, to ensure that the position accuracy of each turn of wire reaches ±0.05 mm, which greatly improves the quality and performance stability of the coil, and makes the crossover more accurate in the audio signal processing.

In terms of improving winding efficiency, REPOSAL has developed a unique high-speed winding technology. Thanks to the use of an advanced motor drive system and an efficient drive, the winding speed of the winding machine is increased by 30% compared to conventional models. At the same time, combined with the intelligent control system, continuous and uninterrupted winding can be realized, which greatly shortens the winding time of a single coil. For example, a common divider coil that used to take about 10 minutes to be wound by hand, but only 3 to 4 minutes with REPOSAL's winding machine significantly improved production efficiency and provided strong support for large-scale production.

In terms of versatility, REPOSAL's crossover coil winders are highly adaptable. By designing replaceable winding dies and flexible parameter adjustment functions, it is possible to wind a wide range of divider coils with different specifications, shapes and parameter requirements. Whether it's a crossover coil for a miniaturized audio device or a crossover coil for a large professional audio system, high-quality winding can be achieved on the same winding machine. For example, for coil skeletons with different inner diameters, outer diameters and height requirements, the winding machine can quickly switch production modes through simple mold change and parameter setting to meet diverse market needs.

In addition, REPOSAL also pays attention to the research on the convenience and intelligence of the winding machine. A concise and easy-to-understand human-computer interface has been developed, so that operators can master the operation method with only simple training. At the same time, the winding machine also has intelligent fault diagnosis and early warning function, which can monitor the parameters in the winding process in real time, and once there is an abnormal situation, such as wire breakage, abnormal winding tension, etc., it will immediately send out an alarm and prompt the cause of the failure, which is convenient for the operator to deal with in time and reduce the risk of production interruption and equipment damage.